Cooling

Miroslav Sanytrák/Boris Dacko/foto J.Křenek | 7.3.07 | Chladiče oleje

F1 constructors

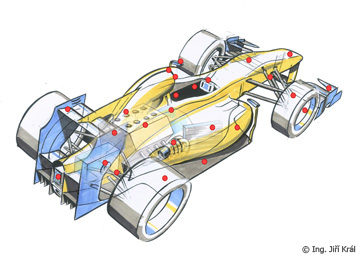

Similarly to any other combustion engine, the F1 motors produce a lot of heat that needs to be damped. This way, about a third of the fuel energy is wasted. Obviously, the heat warms up all neighbouring parts - cylinders' walls, pistons, valves etc. If the engine crossed a certain level, the affected parts would get far too dilated and consequently they would jam. The high heat would also undoubtedly cause the burn-out of the pistons, melting of the igniters and much other destruction that would immediately stop the engine. If the manufacturers were allowed to use some exotic high-temperature proof materials based on carbon or ceramics, the engines might work at higher temperatures. Unfortunately, the FIA regulations only allow iron, aluminium and titanium. The fluid flows through channels in the engine, collecting heat from the surrounding, leading it further to the cooling circuit. The water pump presses the fluid to the radiators, where it goes through a thick network of tubing. Those are washed by the ram air. The heat is thus transferred from the fluid to the tubing walls and finally the flowing air. The radiators on the sides of the monopost, similarly to the stock cars, increase substantially the aerodynamic drag. Therefore they must not be too large but still be able to damp the waste heat. A lot of attention is also paid to the inlets leading the air towards the radiators. They must be effective but must not have extensive aerodynamic drag again. Their shape to a certain level affects the cooling process and different types are used for different circuits. The difference between the most and the worst effective specification of the radiator inlets can reduce the drag up to 5%, which may mean 0.4 s per lap. Because of weight, the inlets are made of carbon composite and their aerodynamics is designed so that the air speed inside of them reaches 10 - 15% of the car speed.

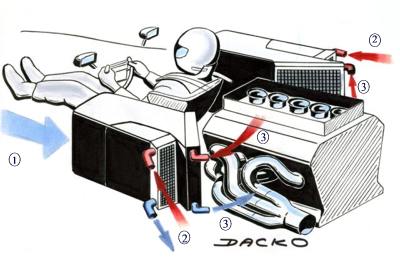

1.Air 2.Oil 3.Water |

Some parts would be difficult to cool down by water. For example piston heads, camshafts etc. Oil spraying is used to cool down such parts, which also lubricates them. The oil heats up, of course, just like water. However, it is very sensitive, as its viscosity can change with the temperature and it can even burn. The hot oil therefore must go through the same cooling system like water. In F1, the water and oil radiators are installed parallelly, one above the other, angularly, i.e. so that they would not take too much space allowing the air inlets to be as small as possible making them aerodynamics friendly. Generally, the oil radiators are much smaller than the water ones. The stock cars' radiators are usually also fitted with fans which lead in the air even when the car stands still. Of course, in F1 any long parking with the engine on is not to be expected, consequently there no fans are used. Therefore during the pit stops portable ventilators are placed into the air inlets.

|

|

|

|