Brakes’ cooling

Miroslav Sanytrák/Boris Dacko/foto J.Křenek | 21.2.06 | Brembo F1 brzdy

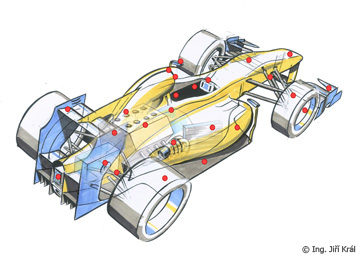

F1 constructors

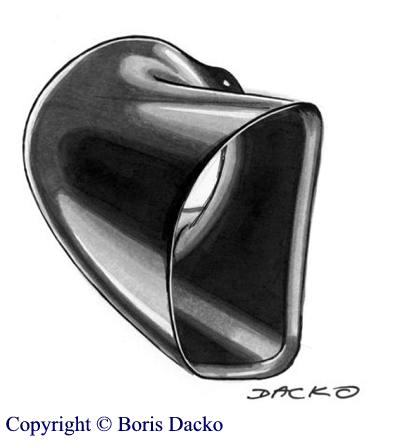

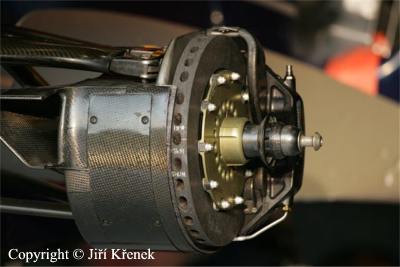

An advanced middle-class car may decelerate from 100 kph at about 38 m. The F1 car is capable of doing the same at 25 m. When slowing down from high speeds the F1 brake system also shows some excellent performance. It can decelerate from 350 kph to 80 kph in only 3.5 s. The huge mechanical energy is transformed into the heat energy, consequently the temperatures of the brakes components reach, compared to a common car, unbelievable values. For instance, the brake discs work at the temperatures of 1000°C. Such temperatures are not within realms of possibility for steel discs, therefore you may find the carbon composite as basic material for brake discs, clampers and friction elements (braking pads). The clampers may also be made of aluminium alloy. However, even the composites can reach their limits. The temperature can be kept within reasonable limits by a sophisticated design of the cooling system. The brake duct leading the air to the brakes sticks tightly to the wheel's pitman and the clampers. The pitman centre, housing the bearings, is mounted to the suspension part by a number of ribs. Such design allows not only for the pitman to be lighter, but also enables the air to flow through (by the ribs) to the brake discs mounted onto the wheel hub. The air gets in through the inner perimeter of the disc into the channelling, leading the air further to the outer openings of the disc. The fast flowing air bears the damp heat away from the disc. Similarly the air also flows through the clampers. To ensure that the air gets to the brake disc and nowhere else, the pitman must be covered by panels made of the light carbon composite once again.

|

|

|